Digital and physical worlds have been two different streams for quite a long time but with the advancement of technology, the boundaries between these two worlds are blurring into non-existence. These two worlds are interwoven so minutely that now they support various technological and industrial activities seamlessly. In context to this costs are reducing and efficiency is improving. In a similar fashion, products have become smarter and services have become more convenient, thanks to Industry 4.0 revolution.

The Industry 4.0 is being touted as the biggest industrial revolution. Its base is connecting highly intelligent and advanced systems to create a digital value chain. This is enabled by the Internet of Things (IoT). Industry 4.0 combines communications, data elements, IT and physical elements transforming traditional machinery into smart technologies.

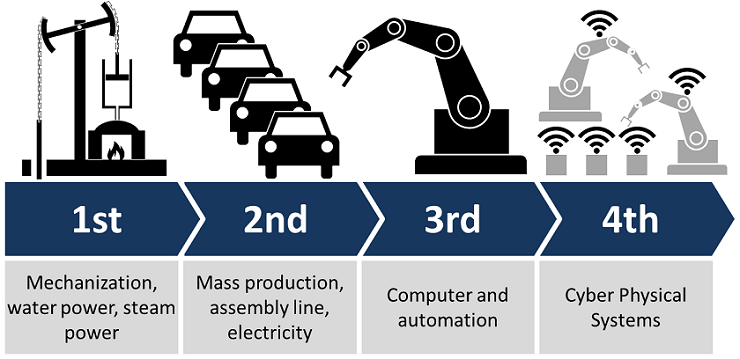

The Industry 1.0 during the 19th century is the base of industrial revolution where all the mechanical and technical production was powered by water and steam. All the developments began from here.

With the help of electrical energy, Industry 2.0 progressed around the 1850’s till World War I. Mass production was done by the division of labor that was powered by electrical energy. Steel was also introduced during this era.

After which came the era of Industry 3.0 around 1950’s where technology progressed at the speed of light. Production during Industry 3.0 was automized with the help of electronics and IT. Smart devices were developed and internet boomed in this era.

Today, we are a part of the biggest industrial progress in history. Industry 4.0 significantly interconnects the digital and physical worlds with the help of IoT – Internet of Things. Social media, big data, analytics, cloud storage, sensor networks, everything is interconnected. Industry 4.0 is not a new technology. It is a determined and notable approach to achieve results that were impossible in history with the help of technological advancements.

Industry 4.0 – Industrial Revolution

General Electric (GE) released the term ‘Industrial Internet’ describing how big data analytics is combined with the Internet of Things (IoT) to produce more opportunities for industries. One of the first times the word ‘Industry 4.0’ was coined by Germany in 2013. A government memo released mentioned a plan to totally computerize the manufacturing industry without much of human involvement.

The SMLC – Smart Manufacturing Leadership Coalition in the United States is a non-profit organization advancing to progress in this area. It includes various manufacturers, technology companies, suppliers, universities, laboratories and government agencies. It aims to construct a smart and open manufacturing platform for information applications.

Industry 4.0 is also known as the ‘smart factory’. The connection of computers and automation helps develop the robotics field greatly. Robotics remotely connects to computer systems enabled with machine learning algorithms. Thus it helps in controlling robotics with very less input from the human operators. The ‘smart factory’ is where cyber-physical systems monitor all the physical processes of an industry. It also takes a decentralized decision with the help of technology, big data, and analytics.

Industry 4.0 – A Wave of Developments and Innovations

With the light-bolting progress speed of Industry 4.0, we are experiencing technologies like never before. The world is progressing towards automation, robotics, AR (Augmented Reality), VR (Virtual Reality), gesture and sensor controls and much more. This is the biggest wave of development and progress in the history of Industrial Revolution.

All we can say that this revolution is towards its maturity stage and we can expect some path breaking innovations and developments.